Vessel Condemnation: Ensuring Safety and Compliance with Professional Commercial Diving

At Thai Subsea Services Ltd., we specialize in providing Class-approved, thorough, and impartial underwater inspections that ship owners, Classification societies, insurers, and port authorities rely on when the future of a vessel hangs in the balance.

When serious structural concerns arise — excessive corrosion, buckling, cracking, or suspected hull failure, to name a few — a properly executed condemnation survey (or condition assessment leading to potential dry docking/scrapping/condemnation) becomes essential.

Although considered a ‘last resort’ option, it is a harsh reality some may need to face when their vessel no longer meets the minimum safety, structural, or operational standards required for continued service. This process is essential for several compelling reasons tied to human life, environmental protection, economic realities, and international maritime regulations.

Our team delivers the valuable data needed to make informed, defensible decisions.

Why Vessels Reach the Point of Condemnation and When Condemnation Becomes Essential:

Ships operate in one of the harshest environments on Earth. Over time, the combined effects of:

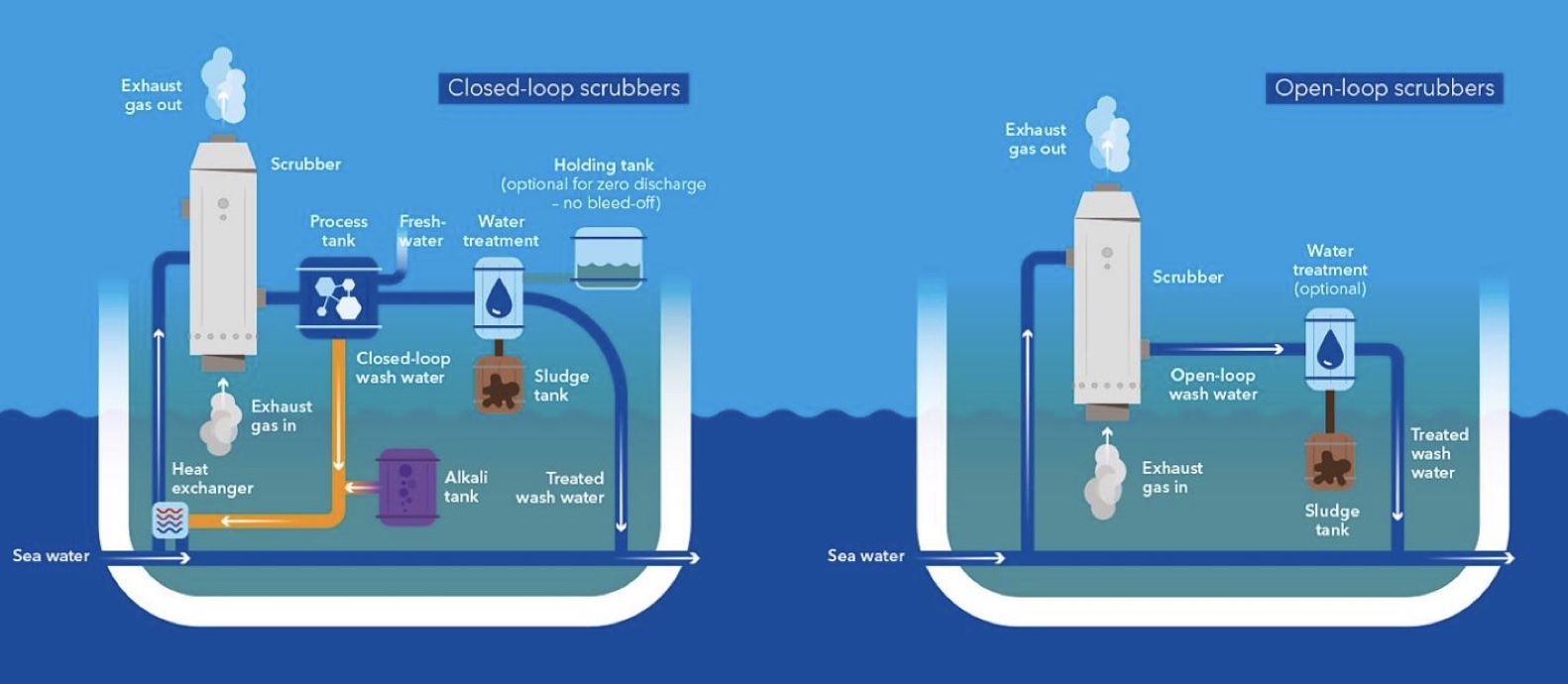

- Progressive corrosion and deterioration (especially in ballast tanks, scrubber systems, cargo holds, and shell plating) – higher risk in older tonnage and when vessels reach 20+ years of operations

- Fatigue cracking from cyclic loading

- Accidental groundings, collisions, or heavy weather damage

- Poor or untimely maintenance protocols or poorly preformed repairs

When safety risks become unacceptable — Classification societies and flag states may require a formal condemnation survey.

Condemnation surveys are triggered by:

- Serious reported vessel problems or anomalies

- Major catastrophes, including, after groundings, collisions, explosions and fires

- Failed port state detentions with no viable repair path

- Routine Class surveys revealing unacceptable defects

Cracks and through-hull penetrations

Rudder damage

Our Professional Condemnation & Condition Survey Process

We follow strict Class-approved procedures (ABS, DNV, Lloyd’s Register, etc.) using surface-supplied commercial diving techniques.

Pre-Dive Planning – Review of vessel plans, previous surveys, repair history, and known problem areas.

General Visual Inspection (GVI) – Focusing on the damaged areas first, but expanding to all subsea ares of the vessel (hull plating, appendages, sea chests, rudder, propeller, thrusters, etc) Incorporating different types of media capture, such as live CCTV and high resolution still photography.

Close Visual Inspection (CVI) – A close-up examination of the damage and its surroundings to determine the root cause and conclusions at the point-of-failure. Divers may deploy a myriad of tools and techniques to help assess conditions, including, rulers & tapes, verniers and gauges (pitting, thickness, feelers). If required, Magnetic Particle or other various Non-Destructive Testing (NDT) techniques may be carried out.

Conclusions – A non-biased final report is drafted based on the diver’s findings. Results may include sketches and mapped drawings in addition to the captured media. This report may include executive summaries, remedial recommendations or repair solutions.

Aloft repairs

Condemnation as a Last Resort

Safety comes first – But repairs can often restore it!

At the end of the day, condemning a commercial vessel isn’t about scrapping “old iron” — it’s about drawing a firm line: no vessel is worth more than the lives it could endanger or the environment it could destroy.

Commercial vessels are valuable assets and extremely expensive. Scrapping means loss of revenue and charterer contracts and high demolition costs (even if offset by scrap steel sales).

However, its not all doom and gloom. Unless a vessel is totaled beyond economical repair – when repair costs exceed remaining value – or vessel is deemed utterly unseaworthy, there usually is always an option to prolong a vessel’s lifespan.

“Condemnation” merely means that the vessel is currently unfit, or unsafe to continue its intended purpose.

Depending on the severity, a condemnation notice could be in the form of a formal Class condition, which may require the ship owner to act immediately to remedy the situation, or in less serious cases, given leeway to make the necessary repairs at her next drydock.

Repair options

- In-Water Repairs – A trusted commercial diving firm such as Thai Subsea Services is sometimes asked to perform miracles in the water. In an effort to avoid total condemnation of their vessel and the seizure of all future voyages, ship owners often lean hard on divers to help get them out of precarious situations. Depending on the scenario, a variety of bespoke solutions can be carried by divers to keep vessels in operations, including, underwater welding (for hull penetrations), propeller cropping & straightening, and stern seal replacements, to name a few. Whilst there are endless scenarios where TSS has come to the rescue to save the day, there is still a limit to divers’ capabilities.

- Afloat Repairs – A general terms for maintenance performed while vessel is still in the water, at anchorage or alongside a dockyard. This can cover a wide range of possible repair work such as, major mechanical and electrical overhauls, hull repairs and corrosion treatment. Vessel can be pitched or heeled in this position safely as required. This option may involve assistance from a diving team in conjunction with in-water repairs. This is a great economical option, where speed and flexibility are paramount.

- Drydocking – The only practical option should large scale rectifications be needed. This includes major structural repairs or replacements to the propeller, rudder, hull plating or other major components. While vessel is totally out of the water it offers deep and comprehensive monitoring of repair works in a dry environment. Obvious economic impacts due to high labour and docking fees.

Vessel in drydocks