Why Do Ships Break? Understanding the Factors Behind Ship Failures

Ships are incredible feats of engineering, designed to withstand the harshest conditions of the sea. Yet, despite their massive size, advanced materials, and cutting-edge technology, ships still break or fail.

While the title of this blog may seem broad or blatantly obvious, it is worthwhile discussing the causes of these failures, which can range from human error to natural forces, mechanical breakdowns, structural weaknesses, and how proper maintenance and subsea intervention can help to mitigate them.

In this blog post, we’ll explore some of the primary reasons why ships break, and what can be done to prevent these catastrophic events.

1. Structural Stress and Fatigue

1. Structural Stress and Fatigue

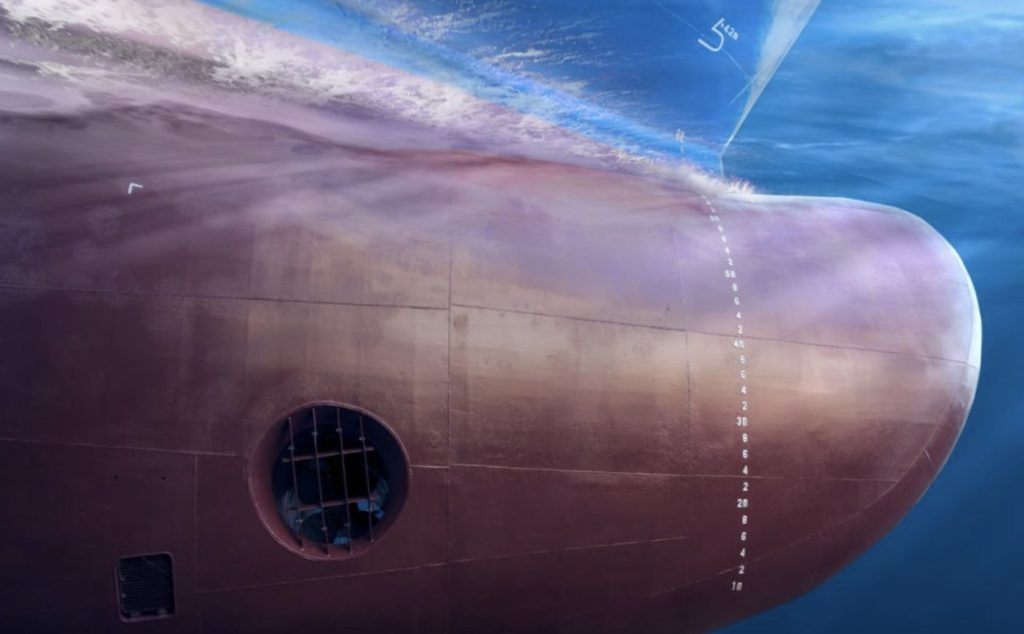

One of the most common reasons for ships breaking is the stress they experience while navigating the open seas. The constant motion of the vessel—especially when moving through rough waters—causes stress on the ship’s structure. This is particularly true for large ships like tankers, container ships, and cruise liners, which are subject to immense forces.

Over time, repeated flexing and bending of the ship’s hull can lead to metal fatigue, where small cracks or fractures develop in the hull.

These cracks can grow over time and eventually cause the ship to break apart, especially if the ship is subjected to unexpected stresses, like an intense storm or collision.

Preventive Measures: Regular maintenance, inspections are essential at spotting small problems before becoming catastrophic failures. Also, the use of more fatigue-resistant materials (like advanced alloys and composites during the construction phase) can help reduce the risk of structural failure. Ships are often designed with redundancies, meaning multiple safety measures are in place to prevent catastrophic breakdowns.

2. Corrosion

2. Corrosion

Saltwater is one of the most corrosive environments on Earth, and ships are continuously exposed to it. Over time, the steel hull of a ship and its appendages (also steel) will corrode, weakening their structure and compromise their intended functions.

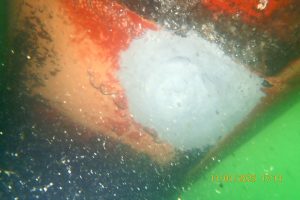

This corrosion often occurs below the waterline where it is harder to detect and repair. Without proper maintenance, this can lead to the thinning or pitting of the hull, making it more vulnerable to punctures or cracks.

Preventive Measures: While corrosion inspections can be routinely carried out by a vessel’s crew. Regular underwater inspections should also be conducted to look for signs of damage or loss of coverage to the vessel’s anti-fouling and coatings below the waterline.

These inspections will highlight any areas exposed steel or those areas susceptible to corrosion. Any corrosion that is found can be tested via thickness and pitting gauges and a scheduled inspection program can be put in place to monitor corrosion progression. For areas that are found extremely corroded, major repair intervention may be required to completely replace the failed hull plating.

Many modern ships are now built with increasingly advanced corrosion-resistant coatings, and efficient cathodic protection systems to help minimize the effects of corrosion.

3. Human Error

Human error remains one of the leading causes of ship accidents. Navigational mistakes, failure to follow safety protocols, poor decision-making during high-stress situations, or even basic negligence can lead to shipwrecks. For example, if a ship sails into dangerous waters without properly assessing the weather conditions, or if the crew fails to manage the load properly, the consequences can be disastrous.

In some cases, human error has led to ships colliding with rocks, reefs, or other vessels, causing significant damage or even sinking. Misjudging weather patterns or failing to understand the limits of the ship’s capabilities (e.g., its weight capacity or engine power) can also result in a loss-time breakdown.

Preventive Measures: Proper training and continuous drills for the crew are essential for minimizing human error. Advances in technology, such as automated navigation systems, can also reduce the likelihood of mistakes. Moreover, a better working culture and more stringent regulations for safety practices can go a long way in improving outcomes.

4. Weather and Natural Forces

The sea is unpredictable, and extreme weather conditions can wreak havoc on even the most robust ships. Storms, hurricanes, and tsunamis generate powerful waves and winds that can push ships to their limits. If a vessel encounters waves or currents higher than its design can withstand, it could suffer catastrophic damage.

In addition to strong winds and high seas, icebergs and shifting ice floes in polar regions can also present a significant risk to ships, especially those not built with ice-breaking capabilities.

Preventive Measures: While we can’t control the weather, modern ships are equipped with advanced weather forecasting systems that allow crews to anticipate and avoid dangerous conditions. Ships are also designed to handle a certain level of stress, but crews are trained to navigate carefully, especially in known storm-prone regions.

5. Mechanical Failures

Like any complex machine, ships are made up of hundreds of components that must all work together to ensure smooth operation. Mechanical failures—such as engine malfunctions, pump failures, or problems with steering systems—can lead to breakdowns or accidents. A sudden engine failure, for example, could leave a ship stranded in the middle of the ocean, potentially putting it at risk for sinking or being hit by another vessel.

Preventive Measures: Routine maintenance is crucial for keeping a ship’s mechanical systems in working order. Advances in predictive maintenance technology allow engineers to monitor and assess the health of critical ship components in real time, detecting issues before they become failures. Additionally, redundancy in key systems ensures that the failure of one part does not result in a total loss of functionality.

6. Cargo Problems

6. Cargo Problems

Improper loading, securing, or transporting cargo can also lead to ship breakdowns. Overloading a ship or unevenly distributing its weight can cause the vessel to list or capsize.

Additionally, poorly secured cargo can shift during transit, destabilizing the ship and possibly damaging the hull or other vital systems.

Preventive Measures: Strict guidelines and regulations are in place to ensure that cargo is loaded and secured correctly.

Modern ships often feature sophisticated cargo management systems, and port authorities are tasked with verifying that cargo is properly handled before the ship sets sail.

7. Collision or Grounding

Even though modern ships are equipped with radar, GPS, and other navigation aids, collisions and groundings still occur. A ship can collide with another vessel, an underwater reef, or even an uncharted obstacle, causing severe damage to the hull. These accidents often lead to flooding, which can eventually cause the ship to sink or break apart if not quickly addressed.

Preventive Measures: Improved navigation technologies, stricter maritime regulations, and better communication between ships and coast guards have all helped reduce the number of collisions. However, human vigilance remains key, as does investing in ship designs that minimize the risk of catastrophic flooding in the event of a breach.

After the Damage is Done

Even with all the preventive measures and necessary safety precautions in place, and even after all the procedures are followed correctly, accidents, incidents and failures still happen.

Depending on the severity and the operating policies of the individual asset holder(s), the procedure for following up after any damage, corrosion, or incident may differ, however, they typically would include the following:

- Immediate mitigation of any present or further damages; arresting of any pending emergencies and identifying and assessing any Safety Critical Elements that may have been effected

- Thorough inspection of the affected areas and or components, with a full damage/risk assessment

- Detailed investigation of the sequence of events leading up to the event

- Create a plan for the renewal, isolation or repair, to restore components back to a safe working state

- Execution of the plan

- Continued monitoring

- Renew operating procedures, and safety & maintenance protocols as required, to minimize the risk of future incidents going forward

Its important to note, in the event where assets owned by two separate parties are involved in an incident, an immediate inspection and subsequent repairs may need to be executed at the request of the insurance companies.

Conclusion

Ships are marvels of engineering, but they are not invincible.

Structural stress, corrosion, human error, extreme weather, mechanical failures, cargo mismanagement, and collisions are all factors that can contribute to a ship breaking down.

Fortunately, advancements in shipbuilding, maintenance practices, and technology continue to improve the safety and reliability of these vessels.

By understanding these risks, the maritime industry can take steps to minimize failures and ensure that ships continue to safely navigate the world’s oceans for years to come.

Furthermore, in many cases subsea intervention, by utilizing divers, can play a major role in the prevention of major incidences. Through regular underwater inspections, divers can highlight any anomalies and execute a repair plan, arresting any problems before they occur.

Thai Subsea Services, continue to strive as a “full service company”. Dealing with situations after an incident is always an uncomfortable and often traumatic time for everyone involved. Our experienced team understand these situations well and work closely with our clients, guiding them through the difficult times. Our divers and technicians are able to advise on the most cost-effective solution, often onsite and are able to execute the work in the shortest amount of time, getting the vessels back out to sea and avoiding any downtime.

In the world of maritime navigation, precision and control are paramount. Whether you’re maneuvering through congested harbours or docking in tight quarters, the ability to command your vessel with confidence is essential. This is where thrusters emerge as indispensable tools for vessel operators seeking to elevate their seafaring experience.

In the world of maritime navigation, precision and control are paramount. Whether you’re maneuvering through congested harbours or docking in tight quarters, the ability to command your vessel with confidence is essential. This is where thrusters emerge as indispensable tools for vessel operators seeking to elevate their seafaring experience.