A rudder is one of the most important components in any marine vessel. It enables the helmsman to steer, control, and direct the ship in the sea.

A damaged rudder poses a high risk to the structural integrity of the ship. Without an efficient rudder, a ship can’t operate properly, even with all other systems intact. The rudder’s function and significance are quite similar to a propeller in that it converts rotational kinetic energy into power.

Sitting at the stern of the vessel and taking abuse from the prevailing vessel movements ahead, it is prone to a slew of anomalies making regular maintenance a must. Because of its location in the rear of the ship and its immersion in water, it is difficult to access from the surface for any type of repair work.

A comprehensive rudder maintenance and repair plan is essential to keep your marine vessel up and running.

If you think your ship’s rudder might require repairs, contact our professional underwater shipping repair company today.

What Does a Rudder Inspection Entail?

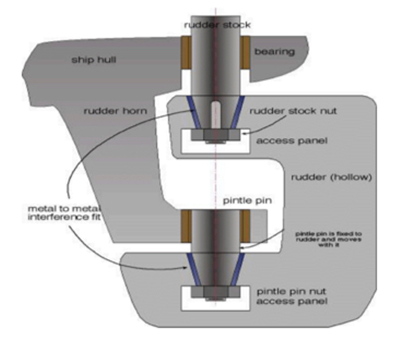

A thorough rudder inspection includes a visual survey of the entire steering gear assembly. Recording deformations, cracks, corrosion and general damage are some of the basic components of these inspections. The pintle pins (the turning axis of the rudder) are also closely inspected for excessive wear and movement and are measured accordingly.

As with the vessel’s steel hull plating, rudders are susceptible to corrosion, thus, an assessment of its cathodic protection systems would be included in these inspections.

There are a lot of small spaces and tight geometries located on the rudder. Known as “niche areas,” these provide an excellent breeding ground for micro and macro marine life. Such growth could impede performance as well as cause troubles for vessels heading for certain ports with strict cleaning regulations.

Typical Rudder Maintenance.

Items of routine maintenance would include replacing depleted sacrificial anodes and pintle access doors that get frequently dislodged. Due to turbulence and cavitation from the propeller – which is situated directly in front of the rudder – excessive wear and pitting may be found on its leading edge. Filling these cavities by the use of underwater welding techniques is quite common.

During operations, the rudder is constantly under stress. Such immense stresses can cause cracking and tearing in the different radii. Tiny hairline fractures, which may not be completely visible to the human eye can be measured using alternative inspection techniques such as Magnetic Particle or Alternating Current Field Measurements (ACFM).

If the rudder is found flooded (a major no-no) commercial divers can assist with the rudder dewatering process. It is even possible to replace the entire rudder itself completely subsea!

Professional Underwater Inspections, Welding, Sealing, and Cutting Services

Thai Subsea Services is a leading company in Thailand focused on offering a wide range of ship maintenance and husbandry services to shipping companies. Our professionals are adept at performing complex underwater remedial work and repairs.

Our services also include underwater hull cleanings for biofouling removal and niche cleanings. Call us at +66 993459494 for more details.