Thai Subsea Services responded to an urgent request from a good client’s vessel regarding a suspected leak in one of the vessel’s bilge tanks.

As the high water level alarms were still sounding, team TSS onboard the diving vessel M/V TSS SHEPHERD were already en route to the injured vessel.

Upon arrival at the vessel, the bilge tanks were already completely flooded, as the internal pumps could not keep up with the incoming seawater.

Since access to the damaged site internally was not possible, the only option available was to survey the source of damage via an underwater inspection before forming a repair plan.

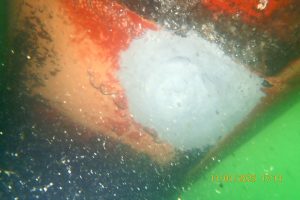

The underwater inspection confirmed a through-hull penetration to the flat bottom of the hull plating underneath the bilge tanks. Based on the data collected from this inspection, heavy corrosion from within the bilge tank had likely caused the erosion on the hull plating, resulting in a 40 mm hole.

Due to the damage’s proximity on the very narrow section of the flat bottom and the excess internal corrosion—resulting in extremely thin hull plating—a repair solution of a threaded doubler plate installation was decided on.

The divers executed the repair, which consisted of making-fast a steel-backed neoprene bung at the penetration site, and then shielding the repair site in epoxy.

This repair was executed successfully. Adequately arresting water ingress so that the bilge tank can be operational again. Due to the quick response and timely execution of TSS, the vessel suffered no schedule delays and can safely complete its voyage before permanent repairs can be carried out in dry dock in a few months.